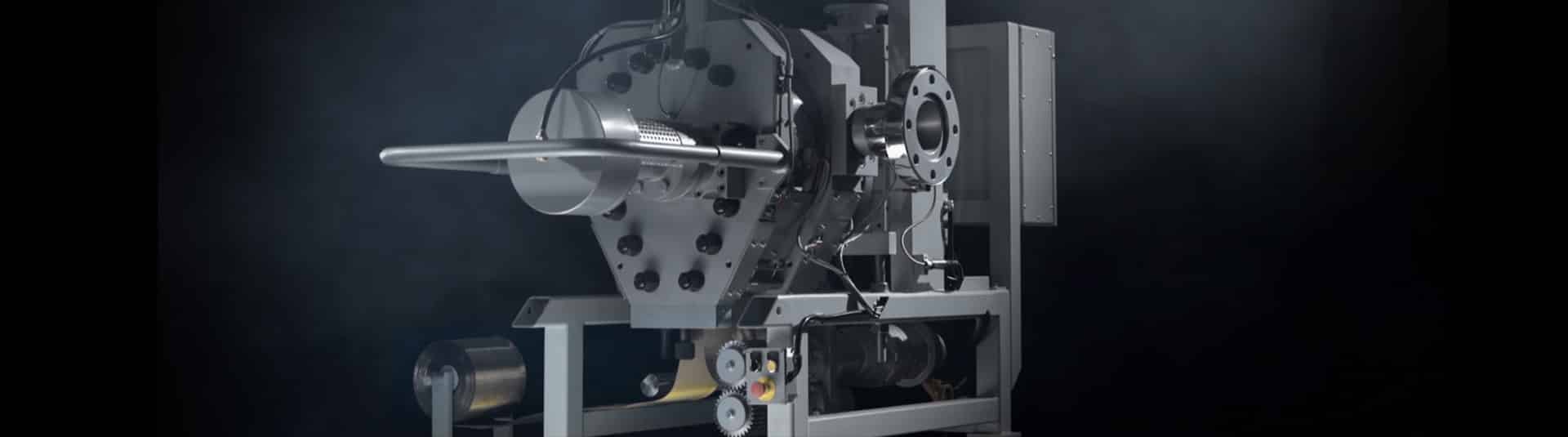

WE HAVE TAKEN OUR MELT FILTER TO ANOTHER LEVEL!

TEN allows you to filter constantly on woven mesh, eliminating build-ups of material and drops in production rates with the additional option of adjusting the screen output. Choosing TEN means you are looking for a new ally in the world of mesh filtration, to guarantee not only superior quality post-industrial material, but also an ally to eliminate the constant presence of the operator, thus facilitating daily work.

TEN is FIMIC’s automatic melt filter, capable of blocking even the smallest of contamination particles thanks to the highly resistant screen, which adapts the temperature according to requirements and based on the material being processed. The adjustable opening of the screen outlet is another guarantee of the quality of the final result.

HOW DOES IT WORK?

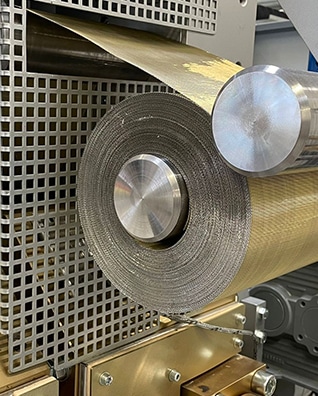

A small scraper near the screen collects most of the dirt and prevents it from breaking when it is changed. The filtering surface, measuring 1,590 cm², allows a low working pressure and thus excludes the risk of quality losses. The possibility of adjusting the speed of the screen change, by setting a pressure which when reached causes the screen to be automatically changed, allows the work process to be adapted to the material being filtered. The screen is held in place by this pressure, when the change takes place, without the need for additional closing systems.

The screen is marketed with a minimum filtration of 60 microns/230 mesh. But TEN can adapt to inferior filtrations as well, if the screen is produced by industry experts. Fast opening when needed is also guaranteed, without the use of special tools or manual skills, because FIMIC also supplies a pneumatic screwdriver at the time of purchase.

mesh: from 230 to 10

SAFETY

TEN embodies the tradition of melt filters plus FIMIC’s innovation which constantly drives us to improve our offer and obtain the very best result without fail.

STRENGTH

TEN is the solution for anyone looking for the highest screen filtration quality with the guarantee of having a strong, cutting-edge product that can eliminate material build-ups.

NO BLOCKAGE

No interruption in the flow avoids stress on the plastic material or an increase in the melt temperature which is simply adapted based on the material. A pre-set temperature is, in fact, not required to prevent screen breakage.

EXCELLENT RESULT

All our melt filters are designed to guarantee excellent results and TEN is no exception!

THE FILTRATION SPECIALISTS

Our melt filters adapt to any system, whether new or existing.

We study the most suitable model to meet any filtration requirement, based on the level of contamination, type of plastic material processed and the hourly production goals.

Contact us and tell us what you need: we will work out the best solution for you.